With the rapid development of technology, intelligent manufacturing has emerged as a crucial direction for the transformation and upgrading of the global manufacturing industry. KVM systems, as a remote management and control technology, are gradually becoming one of the key systems for the digital upgrade of factory production lines.

In intelligent manufacturing scenarios, KVM systems enable remote monitoring, control, and management of production line equipment, significantly enhancing production efficiency and equipment utilization.

Production Line KVM Solutions

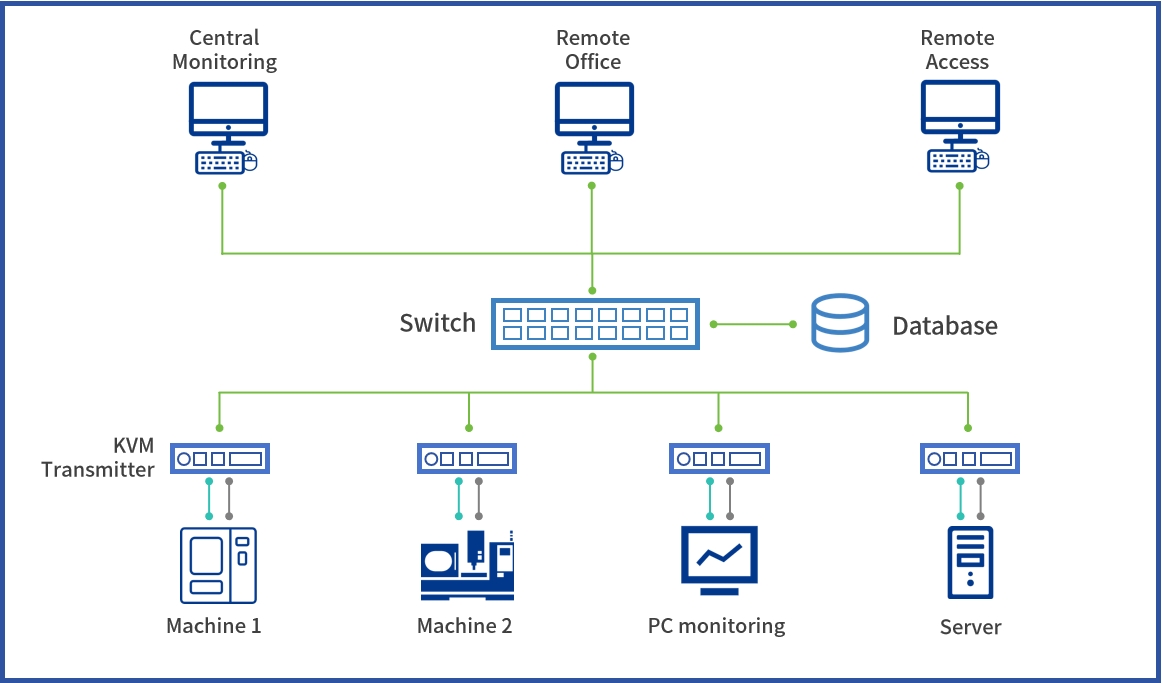

Currently, SimLine's KVM Over IP system is highly suitable for factory workshops. It simplifies user operations and enables remote monitoring and control of production line equipment, greatly improving production line management efficiency.

This system utilizes KVM Over IP input devices and software output ends to uniformly control and manage signals or devices such as audio, video, keyboard, mouse, and RS232 through advanced network technology.

During system design, we minimized the number of devices used to reduce user costs:

On the hardware side, we employed KVM Over IP input devices equipped with HDMI/DVI/VGA video interfaces tailored to production line equipment needs. High-performance image processing engines ensure end-to-end latency below 60ms.

On the software side, SimLine's remote centralized management and monitoring software enable easy scheduling and monitoring of the entire production line on output devices. The software boasts strong compatibility, low network and memory usage, providing a zero-latency real-time access experience.

Through remote access and control technology, technicians can remotely operate production line equipment and monitor equipment status without being physically present, enabling more precise production oversight, optimized resource allocation, and improved work efficiency.

Broad Application Across Multiple Scenarios

KVM production line solutions demonstrate promising application prospects and unique value in numerous scenarios, serving as a key driver for the digital upgrade of factory production lines and enabling enterprises to achieve more efficient and intelligent production management.

Semiconductor Production Lines

Semiconductor production lines often involve hundreds or thousands of devices, requiring significant human resources and time for monitoring and maintenance. There is a higher demand for unmanned and automated operations. SimLine's system meets the need for 7x24-hour uninterrupted monitoring and command, enabling immediate remote handling of various tasks and improving the human-to-machine ratio.

Automotive Component Production Lines

Automotive component production lines involve complex production processes with high demands for efficiency and equipment utilization. KVM enables unified management and efficient scheduling of production line equipment. Technicians can monitor equipment status in real-time and quickly adjust based on production needs, improving production efficiency and reducing costs.

Electronic Product Production Lines

Electronic product production lines require extensive testing and verification to ensure product quality and performance. KVM Over IP systems can be integrated with testing equipment to build a flexible and controllable central management platform, improving testing efficiency and accuracy. Data analysis provides support for production decisions.